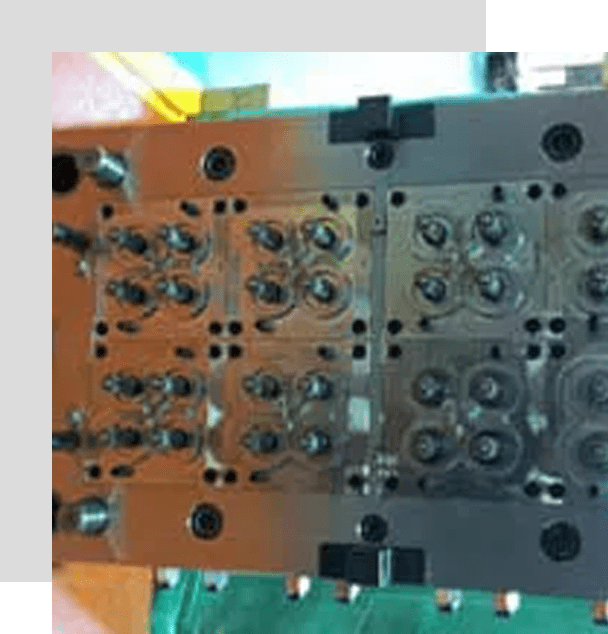

Innovative Mold Designing

Injection Mold Design

Injection mold design is the process of creating the blueprint, or technical specifications, for the mold used in injection molding. This mold essentially acts as a negative mold cavity that defines the final shape of the plastic part.

Here's a deeper dive into the key aspects of injection mold design:

Effective injection mold design requires expertise in various areas:

In essence, successful injection mold design bridges the gap between the envisioned plastic part and the physical mold that brings it to life.

Injection Molding Project Management

Injection mold manufacturing project management focuses on overseeing the entire lifecycle of building an injection mold, ensuring it's completed efficiently, within budget, and meets quality standards. Here's a breakdown of its key aspects:

In essence, successful injection mold design bridges the gap between the envisioned plastic part and the physical mold that brings it to life.

Effective injection mold manufacturing project management helps to:

By applying project management principles, Pro Tech International can optimize the injection mold manufacturing process, leading to reliable and cost-effective production of plastic parts.

Injection Molding Manufacturing Feasibility Study

An injection molding manufacturing feasibility study is a comprehensive analysis conducted to assess the viability of producing a specific part or product using injection molding. It essentially evaluates the practicality, profitability, and potential challenges associated with this manufacturing method for your project. Here are the key aspects of an injection molding manufacturing feasibility study:

Part Design Analysis:

Manufacturing Considerations:

Economic Analysis:

Risk Assessment:

Overall, an injection molding manufacturing feasibility study provides valuable insights to help businesses make informed decisions. It allows them to:

By conducting a thorough feasibility study, companies can increase their chances of success in utilizing injection molding for their manufacturing needs.

Mold flow Analysis

Mold flow analysis is a computer-aided simulation tool used in injection molding to virtually analyze how molten plastic will fill a mold cavity. Imagine a digital test run of the injection molding process before any metal is cut for the mold itself. This analysis helps identify potential problems and optimize the mold design for better quality parts and efficient production. Here's a breakdown of the key aspects of mold flow analysis:

Benefits of Mold Flow Analysis:

Typical Outputs of Mold Flow Analysis:

Mold flow analysis is a valuable tool for injection mold designers, manufacturers, and engineers. It allows them to virtually test and refine the mold design before physical mold निर्माण (nirmaan) - (construction) begins, leading to: